Jacob Quint is the Senior Facilities Manager at Mission Barns, an innovative company that takes animal fat cells and creates plant-based meat. Growing up on a horse ranch, he is no stranger to animals and uses that knowledge to enhance his management and project skills to build his team.

He has been in operational management roles, working as the Facilities Manager for NewTropic, a cannabis manufacturer, and as a general manager for Gravity Wine House.

Here’s a glimpse of what you’ll learn:

- Jacob Quint explains the process of breaking into a new food industry

- What happens to projects when the supply chain is disrupted?

- The value of specialized trade skills

- How the rise or fall of an industry can reshape a state’s demographics

- Jacob talks about the challenges of building a company during the pandemic

- Navigating through remote real estate to build a company location

- The cultural variety of San Francisco for a new brand

- What is exciting to Jacob about the plant-based food startup industry?

- Jacob discusses pursuing your passion for your field and the importance of gaining knowledge

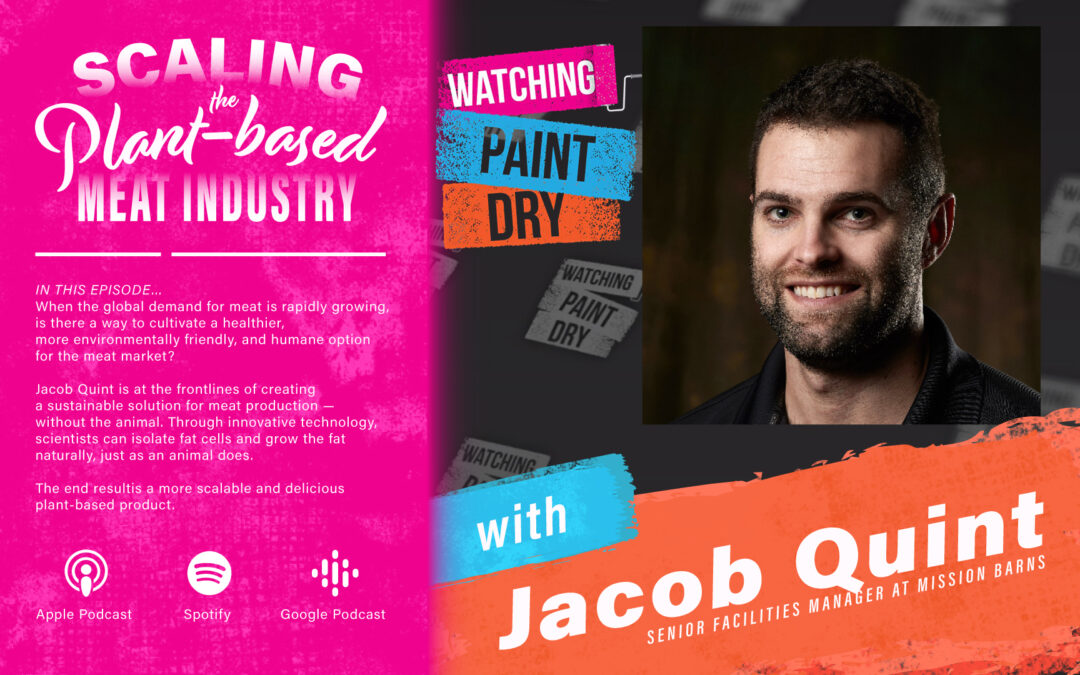

In this episode…

When the global demand for meat is rapidly growing, is there a way to cultivate a healthier, more environmentally friendly, and humane option for the meat market?

Jacob Quint is at the frontlines of creating a sustainable solution for meat production — without the animal. Through innovative technology, scientists can isolate fat cells and grow the fat naturally, just as an animal does. The end result is a more scalable and delicious plant-based product.

In this episode of Watching Paint Dry, Greg Owens joins Jacob Quint, Senior Facilities Manager at Mission Barns, to discuss connecting teams and specialized components for breaking into the plant-based food industry. Jacob talks about how supply chain disruptions affect growth, the challenges of setting up a workforce during the pandemic, and the harvest and cultivation process of growing plant-based meat.

Resources mentioned in this episode:

- Greg Owens on LinkedIn

- Katrina Stephenson on LinkedIn

- McCarthy Painting

- McCarthy Painting Contact No.: 415-383-2640

- McCarthy Painting Email Address: info@mccarthypainting.com

- Jacob Quint on LinkedIn

- Mission Barns

- Niman Ranch

Sponsor for this episode…

This episode is brought to you by McCarthy Painting, where we serve commercial and residential clients all around the San Francisco Bay area.

We’ve been in business since 1969 and served companies such as Google, Autodesk, Abercrombie & Fitch, FICO, First Bank, SPIN, and many more.

If you have commercial facilities in the San Francisco Bay Area and need dependable painters, visit us on the web at www.mccarthypainting.com or email info@mccarthypainting.com, and you can check out our line of services and schedule a free estimate by clicking here.

Episode Transcript

Intro 0:02

Welcome to the Watching Paint Dry podcast where we feature today’s top leaders, industry experts and more to discuss issues affecting facility managers and property owners. Now let’s get started with the show.

Greg Owens 0:22

Hello, everyone, this is Greg Owens with a another episode of Watching Paint Dry. This is where we’re continuing our series of talking to facilities, managers, property owners, business owners, and the entire sort of industry behind properties and buildings. And it’s a it’s a vast industry, as everybody sort of knows. And a lot of people sort of take for granted too, because I think it’s over. Like in the United States alone, it’s over $3 trillion worth of industry out there and work that’s happening. This episode, like all episodes is brought to you by my company McCarthy Painting, we do painting throughout the San Francisco Bay Area, both residential and commercial. We’ve recently done some projects for AstraZeneca, the big pharmaceutical company that makes one of the vaccines, we’ve done some work for Home Depot and Chase bank here again recently. So lots of work going on there. If you’d like to learn more, go to McCarthypainting.com. And I’m really excited for today’s podcast, because I’m going to learn something new about an industry that I that is cutting-edge, and I’ve read about it in sci fi quite a bit. And just so introduce Jacob Quint to the podcast, Senior Facilities Manager for Mission Barns. And we’ll learn more about mission barns here, which makes a what is it? Engineered fat, basically, right, like for food grade eating? And goes

Jacob Quint 1:55

yeah, yeah, basically take animal cells and grow them in a lab and make a plant based meat that tastes good.

Greg Owens 2:04

Right? Yeah.And so you guys are your SIR, you’re the company then I would think is supplying the companies that are out making plant based food tastes better,

Jacob Quint 2:15

we do a little bit of everything. Right now, we are not a supply company, because nobody in this sphere has FDA approval yet. And so we’re pushing to be the first with FDA approval in the United States. And there’s some European countries and some Asian countries that are already starting to work towards the approval process there. So basically, we’re in the r&d phase of very unknown. end goal. End game. So right exciting time to be in.

Greg Owens 2:42

Yeah, it’s a it’s a brand new sort of like, it’s a whole new industry that’s literally growing, right?

Jacob Quint 2:49

It is a really is it’s the company Mission Barns, they decided to take the approach of growing fat cells and rather than the whole animal, the muscle structure and all of that, that you normally consume, it’s most of the flavor comes from that. But anyways, you can use that product, then with the other plant based ingredients to create, essentially could be called a more ethical, more sustainable version, the meat that we all love now. Yeah,

Greg Owens 3:15

that is fascinating. And I just finished a sci fi book, I can’t remember the name of it. But it’s been in a few sci fi books, you know, where they’re traveling into into cell or Strout travel, and they’re trying to make food better, right? Yeah. And make it tastes like something real, to actually have like a cheeseburger on a ship. Right? traveling between the stars.

Jacob Quint 3:36

With this technology, you could potentially do it. I mean, you could potentially set up a little bioreactor and grow, grow meat in your own house, I guess.

Greg Owens 3:45

Right, right. And then you you were saying, as we started this, that you’re on a construction site right now, and you’re you guys are remodeling a building? There?

Jacob Quint 3:52

We are. Yeah, we’re getting the company so far, has been doing a great job of r&d. And we’re getting ready for commercialization of our product. And so with that, we need bigger labs. And so we’re working on setting up our science team within a bigger, more professional laboratory, moving from Berkeley to our new headquarters in San Francisco, to begin the next iteration of the company. So I was brought on to kind of help oversee that transition and make sure it goes smoothly.

Greg Owens 4:19

Yeah, that’s, that’s a that’s a tremendous amount of work. How’s it been with? So, you know, we’re, it’s an interesting time and place in so many ways. I mean, I’m thinking of like, Russia is now sort of invading Ukraine there. And that’s sort of on people’s minds a lot. And I understand there’s nothing we can really do about it, just the people are paying attention to it. We’re still in times of COVID. And then we have this like, um, experience and I don’t know about you, but we keep running into like shortages of paint, and shortages of like, certain types of supplies. We had to wait. We had we remodeled some bathrooms for a client and we waited I’d like just three months to get some last part, the last few parts that we needed to put the sinks together, right? And things like that that would never happen before. Are you? Are you running into those kinds of things in this project?

Jacob Quint 5:11

Oh, very much. So many fabricators, we have custom sinks and things like that, that are supposed to be here, you know, a month ago, and they’re still delayed another month in just every time it gets to the due date, we’re almost expecting calls saying it’s going to be later. Right. And it’s hard, you know, it’s frustrating, you want to push back on it, but there’s really nobody to push back against. And it’s just kind of the way the world is right now.

Greg Owens 5:36

I know, we just kept you feeling so bad, because it made us look not so great. But at least my client was understanding because they’re running into the same problem on their end with, with their vendors and the end themselves, right, like, and so it was it that was helpful, they were just understanding, but going back to them like week after week and going like they’re not in yet. And they’re not giving me a time when they’re gonna agree. And yet,

Jacob Quint 5:58

yeah, we work with a lot of high tech lab equipment. Like, you know, autoclaves are not very high tech, but they have a lot of technical parts on them. And you can build the shell, you can build everything else around it. But until you can get those specialized components from the factories overseas, when you can’t finish the machine. So it’s just ultimately, it’s kind of, you know, I started my work career really in 2007 2008. And during that time, we had a crew of about 80 people who dropped down to about 12 people. And we had to learn to get better with less. And I kind of feel like these kinds of stressors, make you get better at doing what you do. And so you can, it’s, it’s difficult, but you got to find the silver lining where you can.

Greg Owens 6:42

I like that attitude, because finding the silver lining where you can. And it’s just different, right? It’s a different type of business. And it’s let’s find out, we’re doing well having to do a lot more just communicating like, Hey, this is, you know, I sometimes have to remind clients that like, hey, you know, when the President’s calling the shipping industry to find out what’s going on? There’s something wrong?

Jacob Quint 7:04

Yes, right. Yeah, I mean, you can look in the San Francisco Harbor. And you know, it’s not, it’s not one of the busiest shipping areas in the country, and it’s full. And it’s just ships everywhere all the time.

Greg Owens 7:17

Right. Right. And I heard that then I also heard that the price of shipping has like gone up like 10 fold or something like that, for like one container from from, from China.

Jacob Quint 7:28

I mean, this is one of the Painting Contractors on say, here he was, I don’t know, it was it was you and your other podcasts that I was listening to where you’re talking about the price events for Amazon, just like buying up all the events, and they’re doing that with everything, and everything is exponentially more expensive. And it’s getting to a point now where even if you’re willing to pay a premium, you still can’t get them.

Greg Owens 7:48

I still Yeah, we still I still haven’t bought some new bands that I’ve wanted. Somehow the order didn’t go through. And yeah, we’re having we’re waiting.

Jacob Quint 7:56

Yeah. So before coming down here. I worked in a cannabis startup in Santa Rosa. And we were working on freezer vans to ship frozen goods and things like that. And yes, six months. Wait time

Greg Owens 8:07

to get those. Right. Right. Yeah, I Oh, I can imagine that’s especially that’s especially product to for advance. Yes. Yeah, we were waiting for we were waiting for some we had gotten some sinks with the remote hand washing, you know, where you don’t have to, like, touch it. It’s it’s touchless. And so all the parts came in, except for the little tiny gizmo that makes it work. Which means that it’s basically we can’t do anything. You can’t even use the sink. Yeah. It’s not like you could just find like a manual switch on it or anything. There is none.

Jacob Quint 8:41

No, ever since they got rid of all the mechanical engineering and replaced it with electrical, it makes it a lot harder to make things work.

Greg Owens 8:48

It’s so so different. Yeah. And that’s interesting about the cannabis. It’s a big switch for you there from the cannabis industry, which is also a cutting edge industry

Jacob Quint 9:00

to this. Yeah, it is. Yeah, well, I moved to Sonoma County, I kind of moved there to help the family out with a couple things. And after I moved there, that’s the two industries that are there wine and cannabis. And so I started out running a winery. Once I got once I kind of finished that trail of my career, I moved over to cannabis as starting a company I love working at startups with, you know, corporations are great, but you get a lot less freedom and a lot less innovation, I would say on all fronts. And so going to the startup world has been kind of my career career trajectory that has allowed me to hone the skills I needed to go to the next level. You know, like I went to college for a year, didn’t like it, but going and decided I was going to learn to manage people and build buildings. So that’s kind of what I’ve done.

Greg Owens 9:48

I didn’t How did you make that decision? Because that’s not a well known decision path, right?

Jacob Quint 9:55

It’s not but growing up. I grew up on a horse ranch in the middle of Washington State. So Being there, you know, it’s like 50 horses and a bunch of cows. But it’s like, when stuff breaks, you just got to fix it. And I spent my whole childhood kind of building things. And leaving that small town and going on, it’s, you know, I was fortunate enough to have some good mentors, when I was young that kind of instilled in me, if you want to make it, you have to learn something special. Either you get highly technical and very specific in what you’re going to do, whether it’s medical, law, engineering, things like that, or you become very good at the skills that people always need, which is management. And basically, management and project managers. Like if you can understand and talk to the trades and their languages, a lot of other people can’t do that, if you can understand what they need to do their job. Well, if you can look at a wall and see what’s behind there. It goes a long, long way. So just studying that and honing those skills. It just allows so much room for growth, and basically, unlimited choice of industries, every industry needs people who can take care of their buildings, who can build things who can manage people,

Greg Owens 11:03

that that is so true. And that’s so good of you to come to that conclusion. So Young, right? And then and, and I’m saying that because I sometimes take it for granted. And I feel like oh, yeah, like everybody sort of had some similar childhood to mine where you’re like, I was on a roof, but 12 years old, like helping my dad reroute the house, right? Like, and doing all these things, but all of that education comes into play and owning a, a construction and painting business, right? Because I’ve just got so much knowledge and so much knowledge across all the different trades. And and it’s such a valuable skill, like you said, to be able to talk to other trades, and or even figuring out which trade you need. I was just helping a friend who was asking me about smooth making wall smooth that she is like, what’s wrong with my walls? Why this is a problem. And I was like I was told her like, she was wanting to do it herself. And I said, No, you don’t want to do it yourself. That’s misery mudding making walls smooth, is that’s such a technique, highly skilled, labor intensive job, it really is right and not get the mud all over the floor, not get the mud all over yourself. And to get the wall smooth, right? Like, unbelievable. The people that can do that they do it day in and day out and do it so fast, so much faster than anybody know. And it’s more specialized. As I told her, it’s worth it’s worth it, you know, you’re gonna end up spending, she’s gonna end up having to spend so much time just cleaning up after them. Because they’re not very, you know, that she rocked us gets everywhere, right. But it’s such a specialty skill, right? And just having that knowledge, right, like takes that takes. I know, I’ve done it before, right? So I know that that’s incredibly hard.

Jacob Quint 12:46

Yeah, we’re dealing with that right now, in our new our new pilot plant we have, I don’t know what it’s called Idea paint, creative paint. But you can drip dry erase marker on it. And it’s whatever the finishes on, it’s like number four instead of number five. So it’s just not quite perfect and right. You know, it’s we got to make a big decision about whether or not we want to deal with those imperfections or go and get it finished rest of the way.

Greg Owens 13:10

Yeah, you know, that’s interesting. That’s interesting. We do a lot of idea of pain or fuse or different types of writable. Wall pains, right. I actually have one in my own house here to buy and it’s, it’s a rolled on finish. Right? And so on when I see it as Yeah, I mean, it’s great if you can have the wall level five, but because it’s still rolled on finish, it’s not like perfect, right, like, and we’ve actually played with spraying it. So I was wondering if we can get it the glass like finishes. Right? And we can but then it’s good to crazy money and clients. Yeah. A that right? Because they just want to, they just want to be able to write on the wall. Yeah. Yeah. Yeah. So so I’m not sure like, we do a lot of it on level four clients seem to be fine with it. And everyone’s, every once in a while, we get people that want to go to level five with it. And I’m not convinced it was worth the extra money.

Jacob Quint 14:03

Yeah. But that’s good to hear. Because I told them yesterday to just roll with it, or I’m happy, then we will assess it after the fact.

Greg Owens 14:10

Right? We still like we’ll sand the walls, right? And look for any and right kind of look for any imperfections that we can kind of take care of before right but not but not bring it to that level? Five minutes. Yeah. But it’s a great, it’s a wonderful problem is so many companies are using it. We’ve done it to somebody, you know, all the high tech companies want to be able to write on their walls.

Jacob Quint 14:32

Yes. And, you know, being in being in the Bay Area. As you know, it sounds like you’ve been here a long time. He you get a lot of artsy, very forward thinking dreamers, running companies and having that artistic space. You know, it’s good, and they’re nice, and they like to hire local artists come in and make cool things on the walls. And, you know, yeah, here, they really encourage creativity. You know, it’s like Silicon Valley formal. It’s, you know, shorts and a T shirt.

Greg Owens 15:01

Totally, totally. Yeah. And we even we’ve even had subcontracted to the artists that the companies have found, because I have my general contractors, like, you know, they want to make sure it’s insured. Right. And so yeah, well, we’ll bring them in and make sure they’re insured. And then, you know, but they’re just doing art on the wall. The risk is super low. Yes, yeah. But it’s a good, it’s a great, I love it. It’s someone, it’s so fun to see inside some of the buildings and some of the places we’ve been to. And what they’re the creative, the creative energy they have right? On Yeah.

Jacob Quint 15:35

Especially like a company like Mission Barns, where we are really working in this theoretical creative space where we have people that started out as like molecular engineers, they’re biologists, and then they’ve transitioned over to more of the mechanical side, as we try and engineer our way out of issues that you run into with recreating growing conditions for organ like, you know, living organisms in a lab. It’s really allows it to allows you to play in that creative space, you get some really great ideas by just workshop and throwing it all up on the wall.

Greg Owens 16:05

Right? And you and like we mentioned earlier, that it’s a whole industry. So it’s not like you can look at like what are other people doing in this industry, necessarily. I mean, there’s a few players, but they’re all here to

Jacob Quint 16:21

Right. And it’s small. It’s a very, very small industry, it seems big to me, because it’s all I see the same thing. When I was in wine, the wine world seen the norm, but in reality, it’s very small. And this

Greg Owens 16:35

is true for the cannabis industry, too, because that’s enormous.

Jacob Quint 16:39

Very true. It’s cannabis has its whole range of other issues. I mean, it’s the state of California has more has more capacity for growing supply, then the entire world needs cannabis. And so there’s more Canopy Growth, it just, it’s not a sustainable industry in the way it’s regulated right now, because it’s federally illegal, every state has to set up the entire infrastructure for it. So you eliminate, you know, there’s no economy of scale available. And it’s such, there’s so many player. product has historically been so expensive when it comes from the traditional market when you and now people are used to these really high prices. But now you have consumer focus and everything that’s driving prices down just by nature, but the taxes are still so high. It’s just It’s a brutal, brutal industry right now and give it a couple years. And it’ll probably shift and get a little better. But it’s a rough time right now.

Greg Owens 17:34

Yeah. And I always I always, I’m always amazed in that industry. Because when I was like when I first moved to California from New York when I was 16 years old, and that was 1986. It was illegal here. Right. And it was the number one cash crop. Right? Yeah, for California. And that hasn’t changed. Right? Like it’s still it’s still there’s so much of it still being grown. Like you said the price has gone way down. But it’s being it’s still like there’s such an underground newness to the whole industry in so many ways. Not finding not to dispensaries necessarily. But the growing side of it. All right.

Jacob Quint 18:11

Yes. Yeah. It’s still finding its way into other states. And yeah, it’s, you know, until regulations change around that. And, you know, there’s a bunch of different theories about how that should be done. And I kind of stayed away from that more just focused on building their butane extraction labs and their operations. But yeah, they, if you go up, like up north to Willits, you know, and Mendocino County, that town 10 years ago, was a thriving community. And you go there now and all the storefronts are empty, they were all funded by cannabis sales, then there has basically you had a really nice town that was funded by this illegal product, and now the town is kind of a ghost town.

Greg Owens 18:49

And that’s interesting. Yeah. Yeah. No, that’s so true. It’s so true. It just changed the whole demographics of things. And, and, and I would think that what you’re doing Mission Barns, like we’ve been doing some painting for pharmaceutical companies. And it’s complicated, right? Like they have very special needs that a lot of times there’s very special paints and things like that. I wouldn’t think that like the FDA approved facilities, and pharmaceutical companies are probably on par for how complicated they are.

Jacob Quint 19:21

They’re very close. It’s, if you’ve ever worked in food processing or food manufacturing facilities, when you get to the FDA regulation, there’s very strict regulations about the epoxies on the floors, paint on the walls, and a lot of ours, you know, we’re kind of in this in this middle ground between pharma and food. And so we have our, you know, manufacturing in themed rooms and sterile environments, trying to make just like, just like any manufacturing, trying to make the safest product possible for consumption, and ensure that the end user always has a safe experience. Right, and that requires a lot of infrastructure and a lot of investment to make those kind of things melodies. And it’s, yeah, there’s a lot of details that go into it. And you know, following this, we once we go through getting this pilot plan on boarded, the next stage is commercialization at scale. And so then we really get to go play with the big boys after that.

Greg Owens 20:15

Right, then the compliance season goes up even higher, I would think, right, because there’s more, there’s more layers of lead people coming in to check that things are done correctly.

Jacob Quint 20:25

Yeah, lawn traceability alone is a huge task in itself. And that’s just every ingredient, you have to know exactly where it came from, and how it got you, you have to store those records for a long time. And yes, our Director of Quality who’s in head of our GMP and FDA submissions, he is a very, very tired person.

Greg Owens 20:44

I was I went to tour of a processing plant down in Monterrey is a friend’s wife was working there. And we so we got decided got a lot of behind the scenes tour, it was just food. It was vegetables, right? And it’s just vegetables. But what blew me away was like, there was two things. One is they had all the vegetables was on a conveyor belt going through a metal detector, because you know, when you’re eating a carrot, you don’t want to bite into a BB. Yeah, right? Or so our washer, or something that got stuck into food, right? And so they would all went through, and that would shut the entire thing down if that metal detector went off, right. And then they’d have to go find out where where the contamination is. And then the other thing was, they had a scientist on site, and a laboratory where they were constantly checking for ecoli. Right, and other things, but that was the major one I remember. And I didn’t know this, but like almost all food has a little blood has everything you eat has some Ecoli in it. There’s allowable mountains, right? There’s allowable amounts by the FDA, of all this types of bacteria that’s constantly in our environment. But they have to like, he gets the final say on shutting everything down. And like saying, no, stop, we’re throwing all this produce out, because it’s the contaminations too high. Right. Yeah. And I wonder, like, with your industry, is that something you guys have to consider? Or is this stuff so grown in such a way that it’s like, not, there’s no contamination of other foreign elements?

Jacob Quint 22:13

We definitely analyze everything. You know, I don’t know all the details of that science team. And we try and keep that r&d Pretty close to the best when they do. We definitely have a lot of testing protocols defaulter, which comes from stuff like ecoli, and lettuce, really, that comes from a pig walking across the field, go get water.

Greg Owens 22:32

Right. And you don’t have you don’t have those kinds of problems, right.

Jacob Quint 22:37

Yeah. But one of the other things, you have to worry about manufacturing, say like, and this happened with some of the cannabis oils we would make and our butane extraction, all of the machine is stainless steel, so it shouldn’t leach any metal, one part of it was barrel, iron, and when it ran through there, it would leach out cadmium, and then the finished product would have heavy metals in it. So then it’s no longer fit for human consumption. So that’s like from an engineering standpoint, we have to worry about that making sure that the equipment we use is the quality that’s necessary, right. And then it does a food grade stainless steel, it’s not your everyday run of the mill. Right. So

Greg Owens 23:14

it’s a much more expensive processing. Yeah,

Jacob Quint 23:16

it is. It’s more expensive. It’s harder to work with the people that can work on it are more expensive and everything about but it looks amazing. Yeah.

Greg Owens 23:25

Yeah, no, for sure. And and what other challenges are you running into within this new startup? Like, what are you in the times we’re living in here?

Jacob Quint 23:36

Well, the startup world is it’s by nature, it’s chaotic and crazy, which is why I like it. I thrive on chaos. That’s when I’m at my best. And so it’s, it’s the challenges that are here. They’re ones I chose to take on and they deal with ridiculous deadlines, huge goals, trying to march towards them unknown destinations, not knowing exactly what the route we’re trying to take is yet it’s kind of kind of like that problem of building the plane as you’re flying. And, but it’s really, it’s really fun. And if you have the appetite board, it’s a great way to get a lot of experience, learn things you would never learn before and meet a lot of very, very interesting people. I mean, I work with people in operations, one of them has a degree in philosophy from Yale. And he’s just like works in operations. Now. It’s just it’s you get to meet these really, really cool people along the way and doing these startups. But to answer your question, what are the challenges obviously supply chain as we touched on? Yeah, the people keeping people safe right now, you know, you have a very word at a time where a country is very divided on viewpoints. Everybody seems to think you’re an expert on a lot of things. And there really, nobody really is you can only you can only learn so many things so well. And so all the differing opinions about how to keep people safe, how important the safety measures are, you know, that can be tough to navigate. And ultimately, probably the biggest challenge has has been finding people and with our company, especially, because we have scientists that have to be on site, it’s part of our company ethos that all the support staff needs to be on site most of the time, too. So we are not okay having people work remotely for, you know, six months or half a year, things like that. And that’s, it comes down from our CEO, and it’s a mandate, you know, I chose to come work at this company, I wholeheartedly support, if we have to have our scientists in the trenches, we should be here with them, helping you know, all it’s going to take all of us to build this company to where we want to go. So. But he be being mission driven in the way that our company is, we truly are striving to make the world a better place and more sustainable. I mean, my mom owns a cattle ranch in Washington, a small one. It’s a small family, one,

Greg Owens 25:46

your intimate your really intimate knowledge of this industry? Yeah,

Jacob Quint 25:51

yeah, I’m on both sides of it, you know, I support my mom and my sister who run the ranch. But I also love anything that can produce sustainability and a better future for humans, even so many things are making it worse, that we can find a way to make her better, you because of that mission, we get so many people on the team that are mission aligned and so passionate about what they do, it makes it really, really exciting. And because of that, you do end up getting a lot more of the right people.

Greg Owens 26:19

Yeah, and I can see that it also you’re also as a company in this day and age, it’s limiting yourself when you’re you’re saying to candidates that like no, you there’s no option to work from home, you have to go home every day, right? We see that too. Even within my you know, we, we painters can work from home, but even my office, even certain certain project managers and things like that I want to go in, I need them to go into the office and meet with the crews and see people II right, it’s an important aspect of it all, and to show and tell right, so hard to show and tell unzoom how to do some painting projects and things like that, or how to, you know, just even basic things like how to paint a door or something like that.