Peter Belden is the Operations Manager at Blue & Gold Fleet, a ferry and water excursion company that has been serving San Francisco Bay for over 40 years. In 1979, Blue & Gold Fleet began cruising the San Francisco Bay with only three passenger vessels from PIER 39’s West Marina. Since then, the company has expanded to include commuter ferries between Alameda, Oakland, San Francisco, and Vallejo.

Peter Belden is the Operations Manager at Blue & Gold Fleet, a ferry and water excursion company that has been serving San Francisco Bay for over 40 years. In 1979, Blue & Gold Fleet began cruising the San Francisco Bay with only three passenger vessels from PIER 39’s West Marina. Since then, the company has expanded to include commuter ferries between Alameda, Oakland, San Francisco, and Vallejo.

In 2012, Blue & Gold Fleet was selected to operate the San Francisco Bay Ferry System by the Water Emergency Transportation Authority. The company is now the largest ferry and land tour transportation provider for San Francisco Bay’s commuters, residents, and visitors.

Here’s a glimpse of what you’ll learn:

- Peter Belden discusses how Blue & Gold Fleet has been transitioning to full-service following the pandemic

- Peter talks about Blue & Gold Fleet’s current hiring process

- The biggest challenges Peter and the Blue & Gold Fleet team are facing in their transit niche

- How did Peter get started in the industry?

- Peter’s advice for those looking to begin their career in maritime operations

- The generational differences in mechanics and facilities management

- What Peter is most excited about for the summer

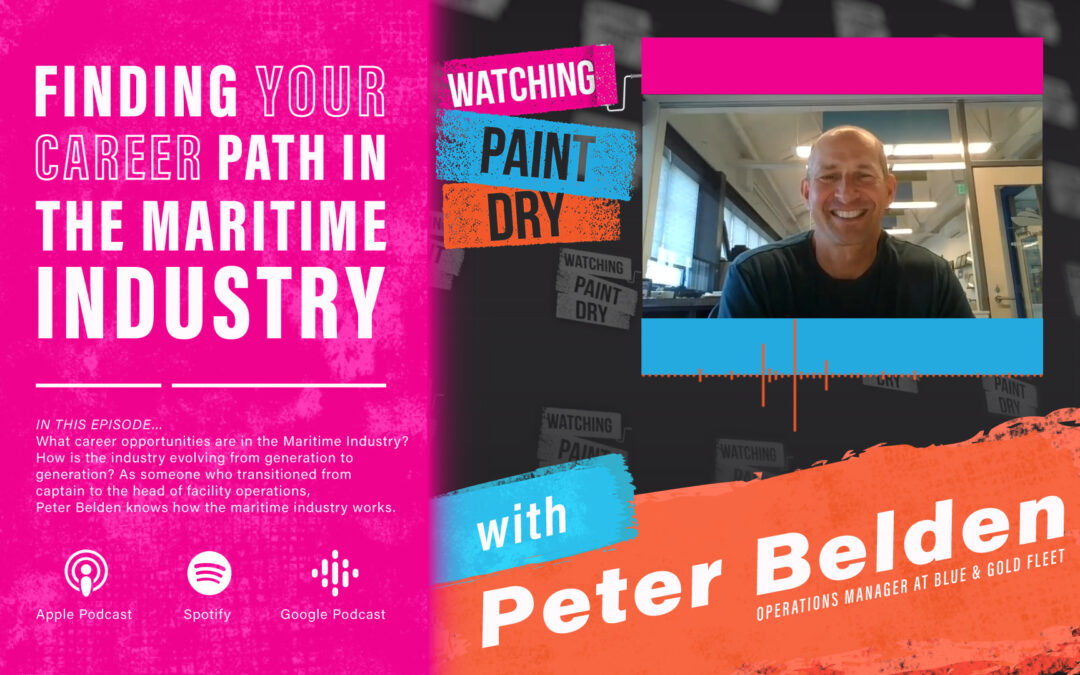

In this episode…

What career opportunities are in the maritime industry? How is the industry evolving from generation to generation?

As someone who transitioned from captain to the head of facility operations, Peter Belden knows how the maritime industry works. There’s an abundance of companies looking to hire new talent and there are many job opportunities, from entry-level positions to senior engineers. According to Peter, some of the best captains started out as deckhands and worked their way up through experience and mentorship. Want to learn more about starting your journey in the maritime industry?

In this episode of Watching Paint Dry, Greg Owens is joined by Peter Belden, Operations Manager at Blue & Gold Fleet, to talk about careers, challenges, and changes happening within the maritime industry. Peter shares how his company is managing rules and regulations with the public, the next big things happening within the industry, and how you can begin your career. Stay tuned!

Resources Mentioned in this episode

- Greg Owens on LinkedIn

- McCarthy Painting

- McCarthy Painting Contact No.: 415-383-2640

- McCarthy Painting Email Address: info@mccarthypainting.com

- Peter Belden on LinkedIn

- Blue & Gold Fleet

- San Francisco Bay Ferry

- California State University Maritime Academy

Sponsor for this episode…

This episode is brought to you by McCarthy Painting, where we serve commercial and residential clients all around the San Francisco Bay area.

We’ve been in business since 1969 and served companies such as Google, Autodesk, Abercrombie & Fitch, FICO, First Bank, SPIN, and many more.

If you have commercial facilities in the San Francisco Bay Area and need dependable painters, visit us on the web at www.mccarthypainting.com or email info@mccarthypainting.com, and you can check out our line of services and schedule a free estimate by clicking here.

Episode Transcript

Intro 0:03

Welcome to the Watching Paint Dry podcast where we feature today’s top facility managers, property managers and property owners talking about the challenges and opportunities of managing hundreds of 1000s of square feet of real estate and how to beautify and improve their properties. Now, let’s get started with the show.

Greg Owens 0:31

Hello, everyone. This is Greg Owens with the Watching Paint Dry podcast where we’re continuing our series of interviewing operations managers, facilities, managers, and all the support service and contractors that support this entire industry. This podcast Watching Paint Dry is sponsored by my company McCarthy Painting. We’ve been in business since 1969, painting buildings houses in in the San Francisco Bay Area. I’ve been working my uncle started this company I started when I was 16 years old, and that was in 1986. So I’ve been doing this for quite a while and excited to have this opportunity to talk to different facilities managers within the industry operations managers and the contractors. McCarthy Painting You can find more by going to info@mccarthypainting.com McCarthypainting.com. And we have painted many, many different types of commercial properties. We are doing a project a big project here for SMG carpet down in Pleasanton. We were doing work for chase paint for coffee and kitchen many more. Check this out on the web. I’m super excited. We’ve been trying to make this happen for a little while. And I actually got to tour Peter Belden’s facility for the Blue & Gold Fleet up in Merritt Island. And it’s an honor to have you on. Thanks, Greg. Good to be here. And our How are you doing? It’s been a while since we talked and I know you were just talking before we got on and you’re busy as everybody seems to be what’s going on for you guys?

Peter Belden 2:13

Well, yeah, we’ve been we’re a lot busier than last time we talked last time we talked, we were pretty much full COVID stand down on the ferry service, which meant two boats running in the morning and two in the evening. Our entire workforce while we were keeping them on the payroll, we were keeping them safe at home and healthy and ready to go once things ramped up. And so we didn’t have a lot of employees coming through here on a regular basis. They were kind of rotating around. So since then, July one we started basically from, from that to what’s pretty much full service for us running every boat, every cruise coming in a lot of service running right now. We’re just seeing how it plays out with the passenger demand.

Greg Owens 2:53

Oh, yeah, yeah, I you know, I can only imagine on your end, because we’re seeing it on our end with all the facilities. So many facilities are calling us saying, Hey, we’re bringing all the employees back. But now we need to paint we need to get a bunch of wall everybody, right? It’s like, yeah, and, and we, you know, doing this sort of rush to get open? What was that for you guys like going from like, basically, you know, having some lead up, but then now the floodgates are still open in your full service facility again? Yeah.

Peter Belden 3:25

Yeah, yeah, it’s, I mean, we kept as far as equipment and the shop and engineering and all that, you know, the boats, whether they’re sitting here or in service, they still need maintenance, and they still need to be taken care of, and exercise and all that. So we kept up all the infrastructure, all through COVID. And so that stuff was all pretty much ready to go. In fact, the votes were probably in better shape they’ve ever been because we had time to do things that we normally wouldn’t have time to do. Cosmetics and whatnot. But the workforce was a different story. It’s you know, bringing people in who had been spending more time at home and more time away from work and suddenly go from that to that 40 hours a week very demanding schedule. And yeah, that’s that’s been what most of my time has been spent with the past week or two is just working with the individuals and getting everybody back up to speed with what their jobs were 1415 months ago.

Greg Owens 4:23

Right, we’re seeing that we’re seeing that within my own company too. Right getting people back up this meet on like, Hey, this is how you work an eight hour day like at the office. Yeah, and you’re not in your pajamas anymore. Man. What, what people don’t know or realize like and I was blown away when I got to see your facility was that you guys can, like, do almost all the repairs necessary on one of those Blue & Gold Fleet ships so you can take out an engine and rebuild an entire diesel. Engine within your facility and put the whole thing back together again. And I’m assuming, though that you have like a schedule of maintenance, that happens almost better than like the same as like a plane in a lot of ways, because it’s a public transportation. And there’s so much public on it, and so many people relying on it.

Peter Belden 5:21

Yeah, without getting too too much into the weeds on it that it’s interesting in in our operation, because the the assets are actually owned by the Water Emergency Transportation Authority, which is a kind of quasi government agency, they get a lot of federal and state money, transportation, money emergency response money to, to build this amazing fleet of vessels and all the facilities for land. So all that is it’s all public money. And so there’s quite a bit of infrastructure built around preventive maintenance, and taking good care of these publicly paid for assets, and a lot of reporting, and documenting and auditing and all that, that we help weather with. So yeah, to answer your question, there’s it’s a really structured maintenance schedule, and it’s all in a big computer database. And it’s all based on engine hours and runtime and other factors. So just that alone without the unexpected breakdowns that happen occasionally that that keeps our staff running all the time.

Greg Owens 6:19

Yeah, because it is his money. And his machinery and it gets it I mean, it there is that always that element of things just breaking down as it kind of as it goes correct. Especially being with the salt water and the wear and tear and that kind of thing that happens. Yeah, yeah. You know, and I know for me, I’m having in my company, we’re having a much more difficult time than I can ever remember and find finding craftsman, right, people that are actually mechanically inclined, we’re talking about printing mechanically inclined, right, which is not not the same level of mechanically inclined that can take a diesel engine apart or transmission apart or something like that. Well, how is it going for you guys in that hiring process? And what’s that look like in this day and age?

Peter Belden 7:07

It’s super challenging. I think everybody I talked to has a unique story. It’s, yeah, it’s it’s tough to find, even even people who may not have the skills out of the box, but they’re really engaged and want to come and work full time. It’s, it’s hard finding good folks to come in that through that entry level as well. We have a lot of job postings on our website. We’re looking for people. And yeah, it’s it’s a little bit of a challenge filling shifts. And that’s not even taking into account trying to find, you know, skilled marine engineers. That’s a whole nother level of difficulty. And sourcing employees for that.

Greg Owens 7:44

Tell me what, what is the difference? Like? So when you have you have mechanics and and skilled marine engineers? What’s the difference in those roles? Actually, it’s

Peter Belden 7:53

interchangeable, it’s the same thing we so we have an engineering department, and it’s a union shop. And so there’s job classes within engineering, we have everything from an entry level sort of skilled assistant, which is maybe somebody who’s kind of mechanically inclined, but they’re gonna start at the bottom and work their way up. All the way through senior port engineers who guys have been working on vessels of this type for for 2030 years. And those are our go to guys. So there’s definitely room for entry level in our organization. It’s just it’s hard to find people right now, just like everywhere.

Greg Owens 8:25

Right? I have, we’re doing a demo project down here in Livermore today. And, and I’ve got to entry people that this is hard work for them. It’s fun watching them sort of like struggle and stuff, and you know, go from high school to now they’re, like, graduated. And they’re like, you know, ripping up carpet and demoing stuff and that kind of thing. And it’s interesting to see, and it sort of reminds me of my youth when I was when I was defeated. But I but I also know so do you guys get a lot of your employees to the maritime Association, because I know like my cousin went through, became a maritime Merchant Marine like does that how is that the correct terminology? Yes, it is. Yeah. So

Peter Belden 9:16

we have a relationship with Cal Maritime up here in Vallejo. That’s the local training academy college that basically produces trained mariners. And that’s one one way we get crew and engineers. A lot of it actually comes through. On the engineering side. There’s some interchanging with facility stationary engineers at landside facilities, some of that over automotive type engineering background, we see a lot of guys coming in with that. On the deck side, it’s generally through the union hall or a direct hire somebody who has a captain’s license and maybe hasn’t worked on boats of the size and complexity before but we’ll start them at the bottom and train them up. Oh, nice.

Greg Owens 10:00

And how about military? Is that? Is that an avenue? Also, I would think that they like coming from the Navy or something like that.

Peter Belden 10:09

Yeah, surprisingly not as much. We get the occasional guy who served his 20 years in the military, and he’s looking for kind of a final career to work another 10 or 12 years. Occasionally we’ll get an application from someone in that situation, but not

Greg Owens 10:22

not that often. Oh, interesting. Interesting. And then what do you see like when it comes to the merchant, the Merchant Marines going through that school? are they running into the same problem? We are that people aren’t even applying themselves for those careers? As much? Yeah,

Peter Belden 10:41

I’m not sure how it’s playing out on the on the bigger scale. So a lot of the merchant mariners coming out of the Marine academies. They’re going deepwater, we call it they’re shipping out, you know, working on big tankers or freighters. Some of them are getting into tug work. I know that there’s a lot of job openings being posted for inland work boat type things other than passenger ferries, so like tugs, workboats, things like that. Crew boats being a magnet for the postings I see. They’re saying they’re having the same situation we are. Right, so you’re competing. You’re like, sorry, go

Greg Owens 11:18

ahead. Oh, you’re competing against like, say, tug the tugboat? Because I know that company. And it’s like, there’s all the time boats in San Francisco is like, it’s somewhat of a monopoly in a way, right? Like, it’s like, they control all access to the Bay in a way. And and that’s a super lucrative career, too. From what I’ve heard, yeah.

Peter Belden 11:41

Yeah, I was gonna say, I almost feel like, we’re still it doesn’t feel like we’re out of this transition from not working during COVID. To working, it feels like that’s hasn’t really, especially California, we haven’t quite pulled out of that yet. And so there’s still these people are getting their heads around the idea of coming back and working full time and being out in the workforce.

Greg Owens 12:01

I always I’ve been thinking the same thing people are are slow to come to want to come back to work if they haven’t been working. They, you know, maybe they’re doing a few more trips this summer or something like that. Yeah, I

Peter Belden 12:15

know. And maybe there’s a permanent mind shift on this. I don’t know that people are well, maybe I don’t want work to be that big, big of a part of my life if I don’t have to. I don’t know. We’re definitely up against some unusual circumstances here.

Greg Owens 12:27

Right? It’s unprecedented times, right? Like we don’t, we don’t really know. And, and I for one, don’t, I haven’t been wanting to what, like I take it day by day, because it’s like, it seems to change so frequently. Yeah. So what other so now that you guys are opening it, we’re running into supply challenges on the painting end, right, running out of just basic sundries and basic supplies and things like that. Is that has that been affecting you guys?

Peter Belden 12:59

Yeah, it has. We have a really good relationship with our engine manufacturers and our supply chain. The real nuts and bolts in our day to day needs is pretty good. I have somebody in the office who works with me who’s great at procuring consumables, and she just worked your tail off, just finding that stuff through through the past few months has been continuing to be difficult. Yeah, sometimes something will pop up fuel filters right now are really difficult for us to get for some reason. It’s just, you know, things. That could be a problem a couple of months down the line if we don’t get the same kind of thing. So yeah, there’s challenge there. Right, yeah, we,

Greg Owens 13:42

we’ve been having to make concessions, like, you know, we can’t get this paint brand. And this, this Sheen, talk to the client, we can get it nice sheen right away, you know, that kind of thing. Or we’re trying to order a head as best we can. We’re trying to stay ahead of it by ordering and keeping our own stock on stuff as we go. And I’m sure you guys You mean, I saw your facility and you have probably a lot of washers and nuts and bolts that you use on a regular basis. I like the idea of a pyramid. Yeah, I like the idea of a pyramid first. And that’s, I should I should look into that more. That would be good. And any other challenges that you’re seeing now that we’re, we’re opening? We’re back to war?

Peter Belden 14:26

Yeah, I’d say one big challenge that I dealt with it I was dealing with it a half an hour ago. It’s an everyday thing is the whole out the masking thing. So public transit, we fall into a whole different set of guidelines from anything that any of the cities or counties that we operate in are going to come down with, they may say, yeah, we’re all good, let’s all open up. But transit is handled differently. And there’s we have a federal mandate to remain masked for all our passengers and our crew members. On board. We just relaxed that a little bit where we open the snack bars and you can kind of do like they do on airplanes. Now you can take mask off and take a sip and then the mask goes back on. And the enforcement of that is really difficult because there’s a lot of different messages out there to the public, kind of like you’re vaccinated, you’re good to go, you know, you kind of pass this Go do your thing. And then as soon as you step on one of our terminals, nope, mask goes back on. And you’re back into that protocol. So it’s actually been a biggest bigger challenge for the cruise, you know, the frontline folks that have to have this discussion and maintain good customer service and good communication with the passengers. But it’s tricky. Everybody’s an individual and coming from a different place with with the whole mask and fast vaccination thing. I’d say that’s one of our biggest day to day challenges right now, because of our niche and transit.

Greg Owens 15:43

Right, right. I’ve seen that a few times myself, even even within certain companies I do work for I just went to it was interesting, because I didn’t I didn’t understand their reasoning, but I guess because they’re dealing with a lot of labor. Like sheet rock facility that sell sheet rock and, and steel, the steel studs for walls and stuff. I walked in no mass, because I wasn’t having been wearing one and all the different things I’ve been going to and they all looked at me like, Oh, you got to get a mascot. I’m like, sorry, guys. I don’t even have one right now. Right like this. This is new to me. Especially here because it hasn’t been that way within the construction industry. Right, like so I can see how I can see any, the employees can run into that problem of having to keep trying to explain things to people. And then it’s like, Hey, we’re under different rules. And it’s hard to continue doing that to a public. That is what some of it is a lot of people I’ve met a real like, No, I’m over it. Like I’m not doing that ever again. kind of feeling right.

Peter Belden 16:49

Yeah. Right. Yeah. Got vaccinated. You know, the, all the health organizations and over overseers of public health messaging have said, if you’re vaccinated, you can hang out with other people, and don’t worry about it. And then we have a different message as soon as you step on the ferry. So yeah, right up against it.

Greg Owens 17:09

Right. And so, and something I’ve been, we talked about this a little bit before getting on the call, but it’s something I’ve been exploring a lot on this podcast is all the different types of careers that are out there, and how people have found those careers, what they’re liking about it, you know, and then like encouraging words around how to get involved, if somebody out there so he’s somebody that’s either transitioning, or a young person that’s coming up, says, Oh, my gosh, that sounds like something I want to do. And what’s your origin story for getting here at the Blue & Gold Fleet?

Peter Belden 17:43

Well, so I started as a captain working a bunch of different companies around the bay, that’s usually the the way people get into the industry. On the deck side, so there’s deck and there’s engineering deck would be deck hands captain’s first aid, that kind of thing working on the text of the boat. Now.

Greg Owens 18:04

Was this a childhood sort of like did you know you love the water and love being on the water and wanted to become a captain because that’s like a, that’s a career, destination and a lot of ways, right?

Peter Belden 18:15

It could be for some people. For me, it’s just happened into it. I’ve always loved the water, I grew up down in the marina in San Francisco and spent my childhood playing around out of Crissy Field when it was still part of the military base there, collecting starfish and buckets and bringing them home and all that stuff. So definitely by the water all the time. But I never really put that together with working on the water, until the opportunity just kind of presented itself randomly and working on deck. Generally the career path for decades, you if you’re going to get become a licensed captain is your work as a deckhand. And you get what’s called tee time, which is just hours on working on a boat. And once you accrue the proper amount of free time, you can sit for a series of exams with the Coast Guard. And you pass all that and a health check and a background check and a bunch of other bureaucracy. And they issue you a captain’s license, it’s good for five years. And once you have your license, it doesn’t mean that you’re able to drive any vessel out there, you still have to work through the ranks and accompany and working with the vessels that way.

Greg Owens 19:16

Right. So if you if you switch, if you switch Tom’s to indifferent to a different shipping company or something like that, you have to start sort of the lower end and work your way back up within that. Right,

Peter Belden 19:28

yeah, it’ll be a learning curve on the equipment and working your way up to seniority and within the company.

Greg Owens 19:35

Right, right. And so tell me about the switch from being captain and then going into facilities and engineering.

Peter Belden 19:43

Yeah, so that was back in. Sorry, I probably would drive drove boats since about mid 90s. up through around 2008 or so. I took a little leave of absence from work as a captain here at Blue & Gold to take a trip up to Britain. Colombia on my own boat, just kind of get away and go try cruising for a summer. So my wife has

Greg Owens 20:07

a sailboat or

Peter Belden 20:08

I say it’s a powerboat. Yep. The trawler, we sold it and got something else. But yeah, so we decided to go give the cruising lifestyle try for a summer just to get away. And that was great came back. And this opportunity was available for an operations manager at our North Bay facility up in Vallejo. And applied got the job. And it was really a great learning experience from there. Because of all the changes that happened since I came to the office, we started at a very basic facility. It was a triple wide mobile home trailer and an Old Navy building here out at Mercer Island as a shop. And very, very rustic. And within about three or four years into my tenure here, we started working on the construction of a new facility, which is where we’re operating out of now, which was built from the ground up and is very complex and advanced. And it’s a great place to work. But it’s a lot of work to keep it up compared to where it started.